28 Aug, 2024

How Advanced Machine Tending is Revolutionizing Production Lines

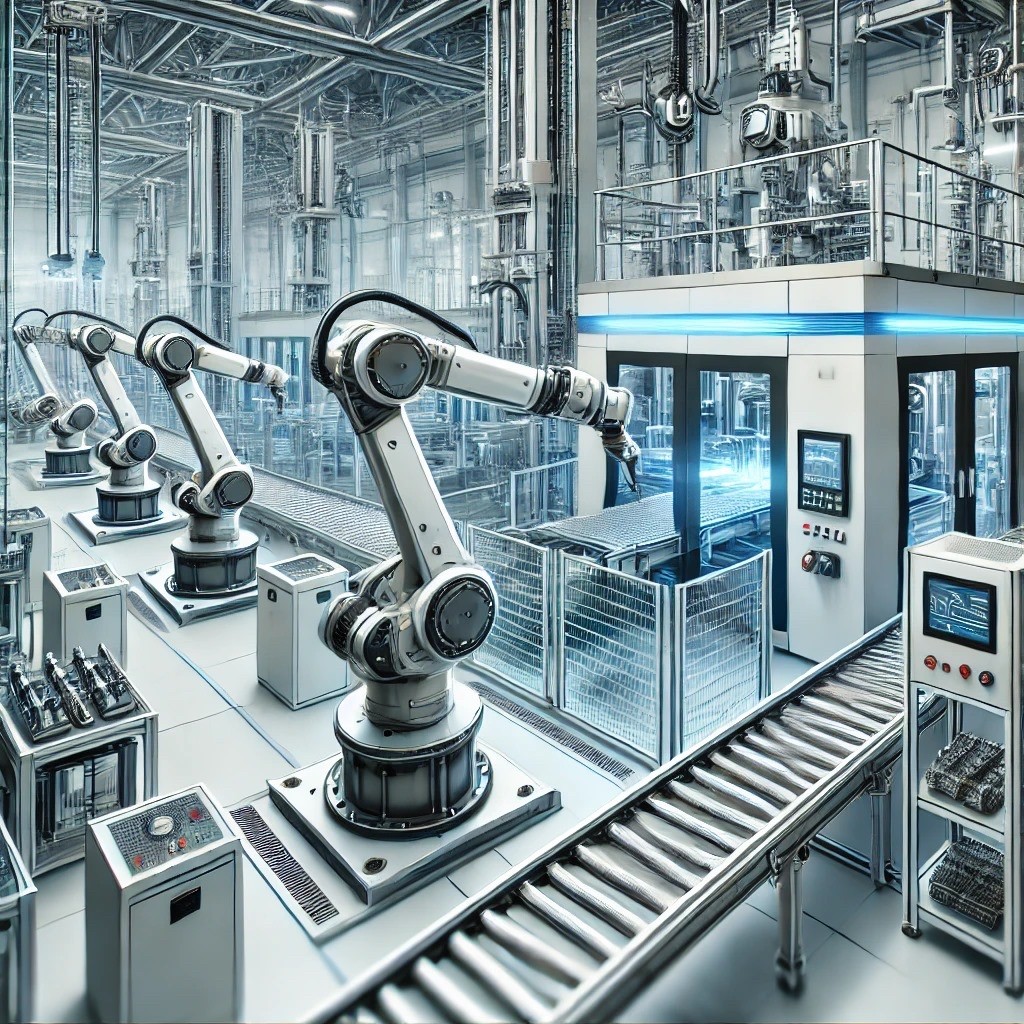

In the evolving landscape of industrial automation, advanced machine tending solutions are transforming production lines by significantly reducing downtime and increasing productivity. These systems are becoming essential to achieving "lights out" manufacturing—where factories operate with minimal human intervention, maximizing efficiency and reliability. This article explores how machine tending robots are revolutionizing production lines, the challenges in deploying these systems, and the solutions that ensure their successful integration.

The Role of Machine Tending Robots in Production Lines

Machine tending robots automate the loading, unloading, and operation of machines on the production floor. These robots work tirelessly, performing repetitive tasks with precision, which reduces the need for human operators and minimizes the risk of errors. This automation leads to a more consistent output, higher quality products, and significant cost savings.

Key Benefits of Machine Tending Robots:

Reduced Downtime: Operating continuously without breaks, machine tending robots ensure smooth and efficient production lines, reducing downtime traditionally associated with human-operated systems (Vention, 2024).

Increased Productivity: These robots maintain high levels of productivity, even during shift changes or after hours. This is crucial in industries with high production demands and tight deadlines (Automate, 2024).

Precision and Consistency: Machine tending robots perform tasks with a level of precision and consistency that is difficult to achieve with human labor, resulting in higher quality outputs and fewer defects (Springer, 2023).

Achieving "Lights Out" Manufacturing

"Lights out" manufacturing refers to fully autonomous factories that operate without human intervention. This is made possible by advanced automation systems like machine tending robots. In such environments, robots handle the entire production process, from raw material handling to finished product assembly.

Advantages of Lights Out Manufacturing:

Cost Efficiency: With minimal human involvement, labor costs are significantly reduced. Robots work continuously without requiring breaks, benefits, or overtime pay, leading to substantial cost savings (Automate, 2024).

Operational Efficiency: Lights out manufacturing maximizes equipment and facility use, enabling production to continue 24/7 without interruption (Vention, 2024).

Scalability: Automated systems can be easily scaled to meet increasing production demands. As the business grows, additional robots can be integrated into the production line without the need for extensive retraining or adjustment periods (Springer, 2023).

Challenges in Deploying Machine Tending Robots:

Initial Investment Costs: One of the primary challenges is the high initial investment required for equipment, software, and installation. However, the long-term benefits often outweigh these upfront costs (Automate, 2024).

Integration with Existing Systems: Integrating new robotic systems with existing production lines can be complex, requiring careful planning and customization to ensure compatibility and optimal performance (Springer, 2023).

Maintenance and Support: Although robots operate autonomously, they require regular maintenance and occasional troubleshooting. Investing in skilled technicians to manage these systems effectively is essential (Vention, 2024).

Solutions for Successful Deployment

To overcome the challenges associated with deploying machine tending robots, businesses can adopt several strategies:

Collaborative Planning: Involving all stakeholders in the planning process ensures that the robot's integration aligns with overall business goals and production needs.

Pilot Programs: Starting with pilot programs allows companies to test the effectiveness of the robots in a controlled environment before full-scale deployment.

Vendor Support: Partnering with reliable vendors who offer robust support services can help businesses navigate the complexities of installation, integration, and maintenance (Automate, 2024).

T-Robotics: Leading the Revolution in Machine Tending

T-Robotics is at the forefront of the machine tending revolution, offering state-of-the-art solutions that are adaptable, efficient, and easy to integrate into existing production lines. With the innovative ActGPT software and advanced controller boxes, T-Robotics’ systems enable natural language programming and real-time adaptability, ensuring seamless operation in diverse industrial environments.

How T-Robotics is Making a Difference:

Seamless Integration: T-Robotics’ solutions are designed to integrate effortlessly with existing systems, minimizing disruption and ensuring a smooth transition to automated production lines.

Scalable Solutions: As businesses grow, T-Robotics’ systems can easily scale to meet increasing production demands, offering flexibility and adaptability.

Comprehensive Support: T-Robotics provides ongoing support and maintenance services, ensuring that their systems continue to operate at peak efficiency.

Conclusion

Advanced machine tending solutions are revolutionizing production lines by enabling higher productivity, reducing downtime, and paving the way for lights out manufacturing. As these technologies continue to evolve, businesses that adopt them will be well-positioned to stay ahead in an increasingly competitive market. T-Robotics is leading this transformation, offering innovative solutions that make automated production not just feasible, but highly efficient and scalable.

References

Automate. (2024). What Is New with Robots in Press/Machine Tending and Material Removal. Retrieved from https://www.automate.org

Vention. (2024). Five Rising Industrial Automation Trends to Expect in 2024. Retrieved from https://www.vention.io

Springer. (2023). Review of current vision-based robotic machine-tending applications. The International Journal of Advanced Manufacturing Technology. Retrieved from https://link.springer.com